Engineered for Performance and Reliability

The core of the Waterloo Biofilter system is our synthetic, absorbent filter medium that is configured as a free-draining, attached growth, biological trickling filter to treat sewage, process wastewaters, landfill leachate, and polish sewage lagoon discharge.

Our Patented, Engineered Filter Medium:

- Stable and consistent over very long periods of time without the need for cleaning or replacement.

-

Maximizes the surface area to volume ratio thereby reducing the system footprint.

-

Accepts very high, long-term loading rates without plugging or compromising treatment – typically up to 10 times greater than sand filters or soils.

-

Simultaneously provides aerobic, anaerobic, and anoxic environments for biological treatment – without air compressors and their high energy use and aerobic sludge production.

-

Absorbs and retains wastewater thereby increasing retention time and providing higher levels of treatment.

-

Maintains biological populations even during periods of no use – enabling consistent treatment levels in seasonal applications like cottages, golf courses, and campgrounds.

-

Eliminates short-circuiting of untreated sewage to the environment during events such as surge flows or power failures.

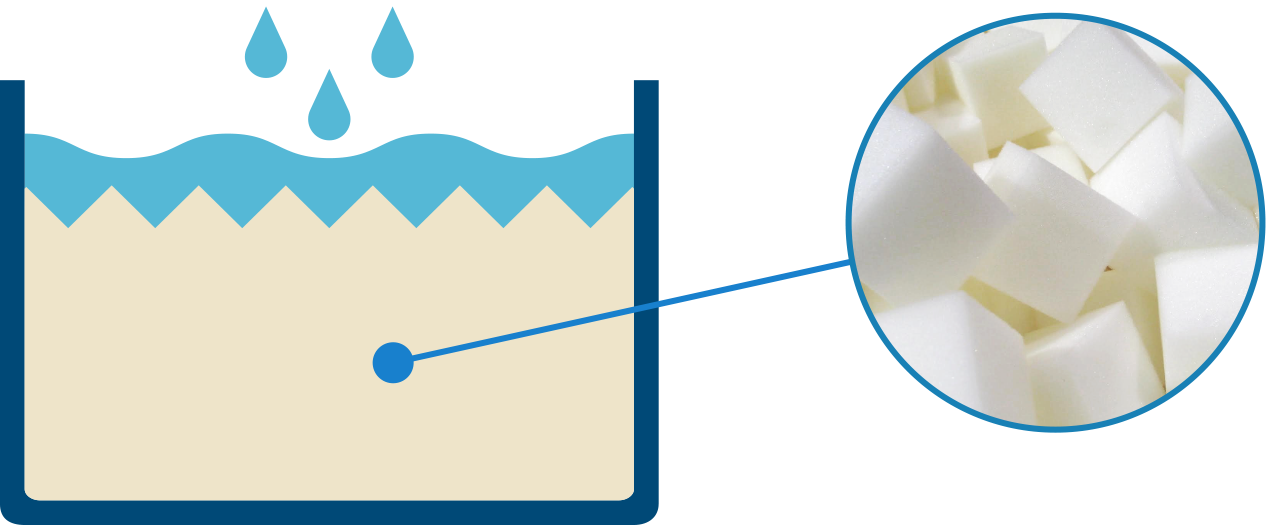

Step 1:

Wastewater is collected and distributed

over the Waterloo foam filter medium.

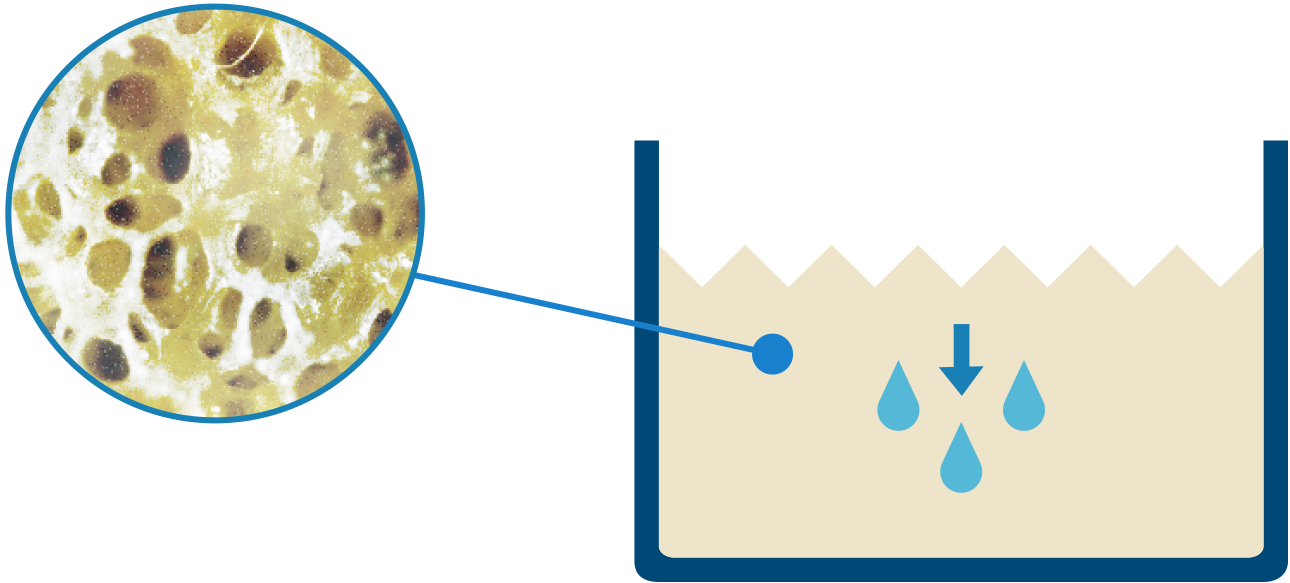

Step 2:

Wastewater is absorbed by and

slowly trickles down through the

foam pieces where natural occurring

bacteria remove contaminants.

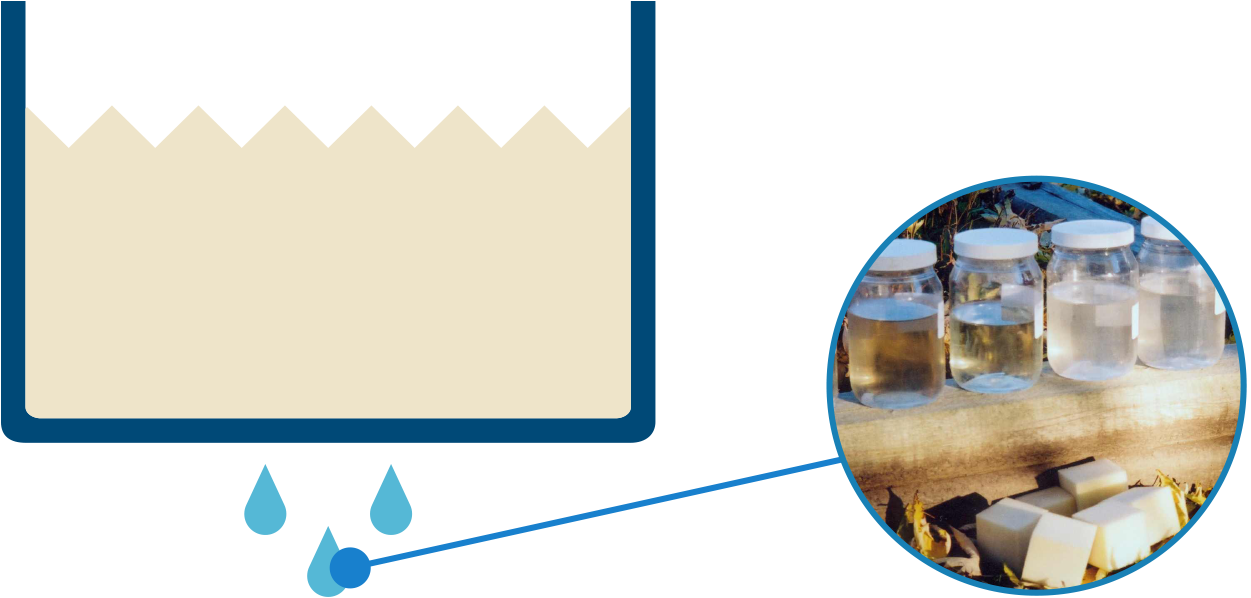

Step 3:

After passing through the foam,

the water is treated and is then

put back into the environment.

The absorbent Waterloo Biofilter filter medium creates an ideal environment for microbial attachment. Beneficial bacteria colonize the interior surfaces of the filter medium where they are protected from predators, desiccation, and freezing. These microbes degrade and oxidize organic pollutants, coliform bacteria, ammonium, and other contaminants as the wastewater is retained in the filter medium by capillarity. Air passively circulates throughout the filter medium providing an aerobic treatment environment without the need for forced aeration.

This attached growth process (also referred to as a fixed film process, intermittent filter, packed bed media filter, or percolating filter) outperforms activated sludge or suspended growth (suspended sludge) processes with lower energy requirements, fewer moving parts, simpler operation, less maintenance, and a better ability to handle shock loads of chemical addition or hydraulic overloads. Of high importance in Canada, the Waterloo Biofilter is proven in frigid -50°C temperatures, treating cold sewage with influent temperatures as low as 3°C. Compared to other media-based trickling filters, the Waterloo Biofilter does not slough off microbes in the form of aerobic sludge, maintains high treatment levels even in very cold climates, has longer retention times, and can accept much higher organic and hydraulic loads without plugging.

Waterloo Biofilters consistently provide tertiary, sand filter quality effluent (< 10 mg/L cBOD & TSS) that is clear and odourless. Highly treated effluent is easily and safely dispersed back into the soil via small, shallow disposal beds or trenches, or can be reused onsite for purposes such as irrigation, truck washing or toilet flushing.